RUBBER TRAP Maintenance

We service rubber traps all over the United States! No matter where you are located, we will come to you.

Sustainable Performance:

Sustainable rubber trap maintenance requires use of Best Available Technologies and Best Management Practices to achieve performance benchmarks safely and economically.

How We Work:

-

1. Call or Email Us

Give us a call at (360) 353-3285, or fill out our contact form and tell us a few details about your range. The amount of bays & lanes are needed to provide an accurate quote.

-

2. Receive a Free Quote & Consultation

We will get back to you within 24 hours to discuss your range’s needs and provide a quote.

-

3. Get a Service Date & Sign Agreement

We will agree upon a service date and send you a formal agreement to sign so that we can get the job done.

-

4. Arrival & Service

We prioritize servicing ranges in a timely manner. Once a schedule is set, we ensure that we meet all time requirements in order to have your range up and running ASAP.

-

5. Lead Gets Shipped Out

Here at FRS we take care of the hassle of shipping and recycling the lead. We weigh all bags of lead on-site and provide a report to the range for all lead yield weights.

-

6. Lead Yield Report

Once the job is complete and the lead has reached it’s destination, we provide you with an extensive report on the lead yield and clearly line out the credit due to the range.

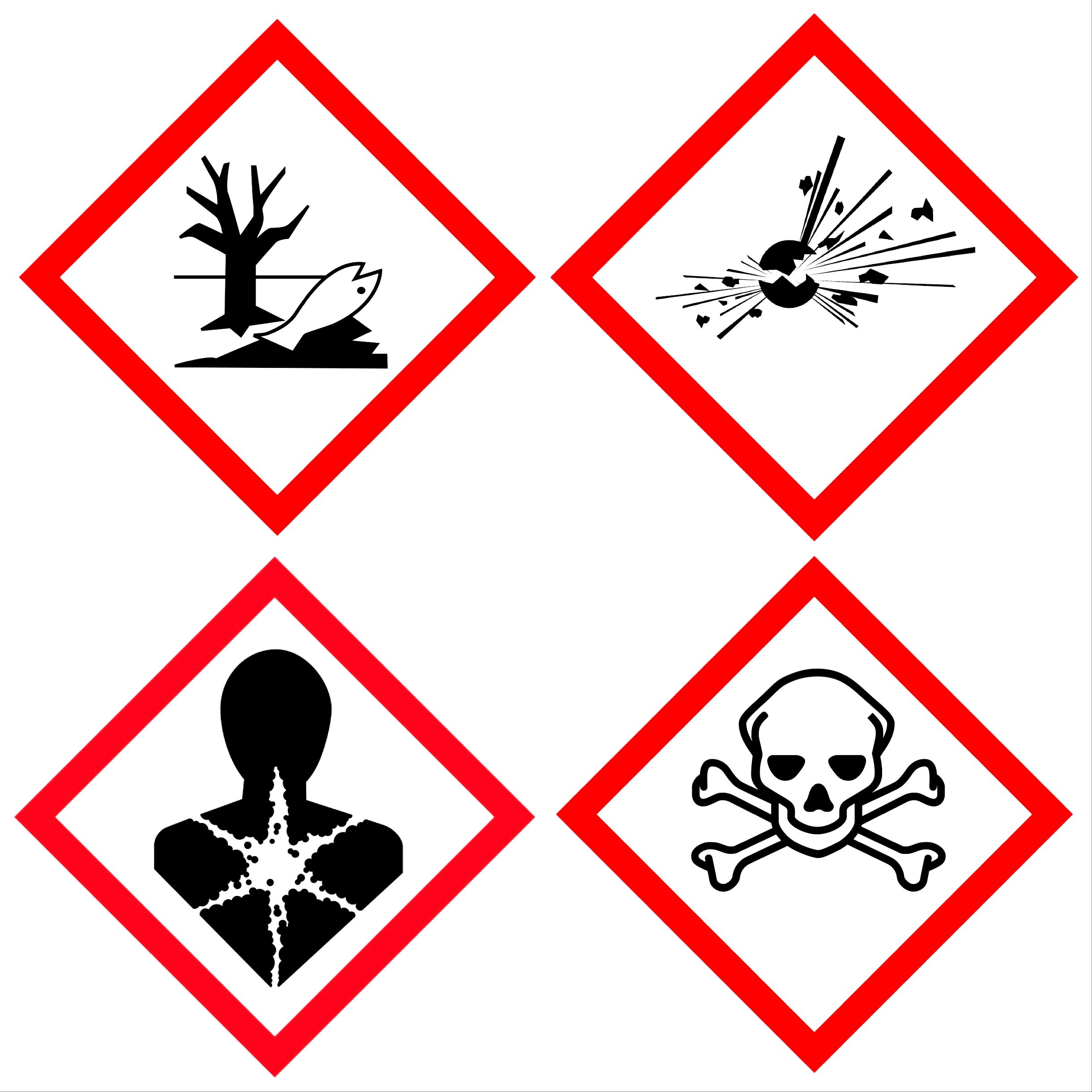

SAFETY

Rubber bullet trap management is inherently a safety management function. Rubber trap safety is determined by:

Depth of the concentrated lead layer;

Accumulation of target paper residues and lead dust

Bullet penetration into new rubber media is about 16”-18”, measured horizontally. Bullets and fragments begin to form a concentrated layer that builds up toward the trap surface. A trap is ready to be mined when the trap density is too high to prevent bullet bounce back, or ricochet.

A properly maintained rubber trap can store up to 3,000 lbs of bullets and fragments per shooting lane—or about 160,000 135-grain bullets.

Improperly maintained traps with excess rubber fines and small bullet fragments are more dense, and the lead layer is too shallow—reducing bullet capacity by up to 75%. These traps must be mined more frequently, driving up costs.

PERFORMANCE

The performance objectives of rubber trap maintenance are simple:

Remove bullets and fragments to be recycled, creating revenue for the range:

Recondition the bullet trap to properly functioning condition:

Complete trap service with minimal to ZERO impact on range operations. Work can be performed on one bay while the other stays open, or at night.

Performance Benchmarks:

Intact media protected from blower damage and 100% restored to the trap

99%+ of large bullets and fragments recycled;

100% of small bullet fragments recycled;

Small rubber fines removed, cleaned to remove lead dust, and recycled;

Target paper residues and CERCLA-regulated lead dust removed and disposed as hazardous waste;

Clean bays when trap servicing is complete

Traps serviced with obsolete technology such as blowers cannot remove the small particulate rubber or bullet fragments that increase density and reduce capacity. Blowers actually chip the rubber, making the problem worse. Bullets penetrate only 10-12” in dense media, reducing the amount of available top cover.

VALUE

Ranges depend on lead recycling to offset the cost of maintenance. Range service providers can either charge a flat fee or charge a percentage of the recycling value. When lead prices are up—everyone is happy. However, when lead prices are down—maintenance costs do not go down unless services providers cut corners on safety and performance to try and protect their profit margins.

FRS will not cut corners regardless of the lead market—but unique in the industry—can purchase lead at stable prices because we are a secondary lead remelter and not just a scrap dealer. We turn scrap bullets and fragments into products that are less dependent on global scrap prices, and can pass that value to our range clients.

Properly managed rubber trap ranges will typically generate a cash return on their lead after covering the costs of:

Lead recycling and trap restoration;

Small particulate rubber processing and disposal;

Target paper hazardous waste disposal;

Optional fire retardant application

Why FRS is qualified to do the job:

Best Available Technologies:

Efficient separator equipment with integrated dust collectors

Mechanical equipment to remove and restore rubber trap media

HEPA air scrubbers

Powered air purifying respirators

Best Management Practices:

Crews are trained, certified and medically monitored for working in lead hazard environments

Containment systems to prevent spread of lead dust outside of the work area

Lead packaging systems to prevent spills and cleanups during transport

Proprietary equipment and systems to manage and minimize hazardous waste

BAT’s and BMP’s are required to protect workers from airborne lead dust, prevent release of lead to the environment and eliminate the physical hazard of heavy lifting. FRS proprietary systems are the only solution meeting OSHA and EPA requirements while simultaneously providing the industry’s best performance for reconditioning rubber traps, recovering bullets and fragments, removing small rubber particulates and removing hazardous target paper residues.

Certification:

All FRS personnel are certified for working in lead hazard environments:

1910.25(L) LEAD AWARENESS IN GENERAL INDUSTRY (LEAD)

1910.1200 HAZARD COMMUNICATION (HAZCOMM)

1910.1025(J)(2)(I) BLOOD LEAD MONITORING (BLL)

1910.134(C)(1)(III) RESPORATOR FIT TEST

1910.132 (ET AL) PERSONAL PROTECTIVE EQUIPMENT

1910.95(D)(E)(G)(H)) - OSHA NOISE STANDARD

FRS IS AN EPA-CERTIFIED LEAD PAINT/RRP CONTRACTOR

Insurance:

FRS carries General Liability, Environmental Liability and Professional Liability Insurance covering range development and maintenance, and can provide certificates of insurance naming our clients as additionally insured.

Qualifications:

FRS and partner AECOM provide the most qualified and experienced multidisciplinary team of engineers, scientists, project managers and skilled trades dedicated to improving the operational, environmental and safety function of shooting ranges:

Certified Industrial Hygienists

Licensed Geologists and Civil, Structural and Mechanical Engineers

Dept. of Defense-qualified Project Managers, Quality Control Officers, Field Supervisors and Site Safety and Health Officers

NRA-certified Range Managers and Range Technical Support Team Members